About Us

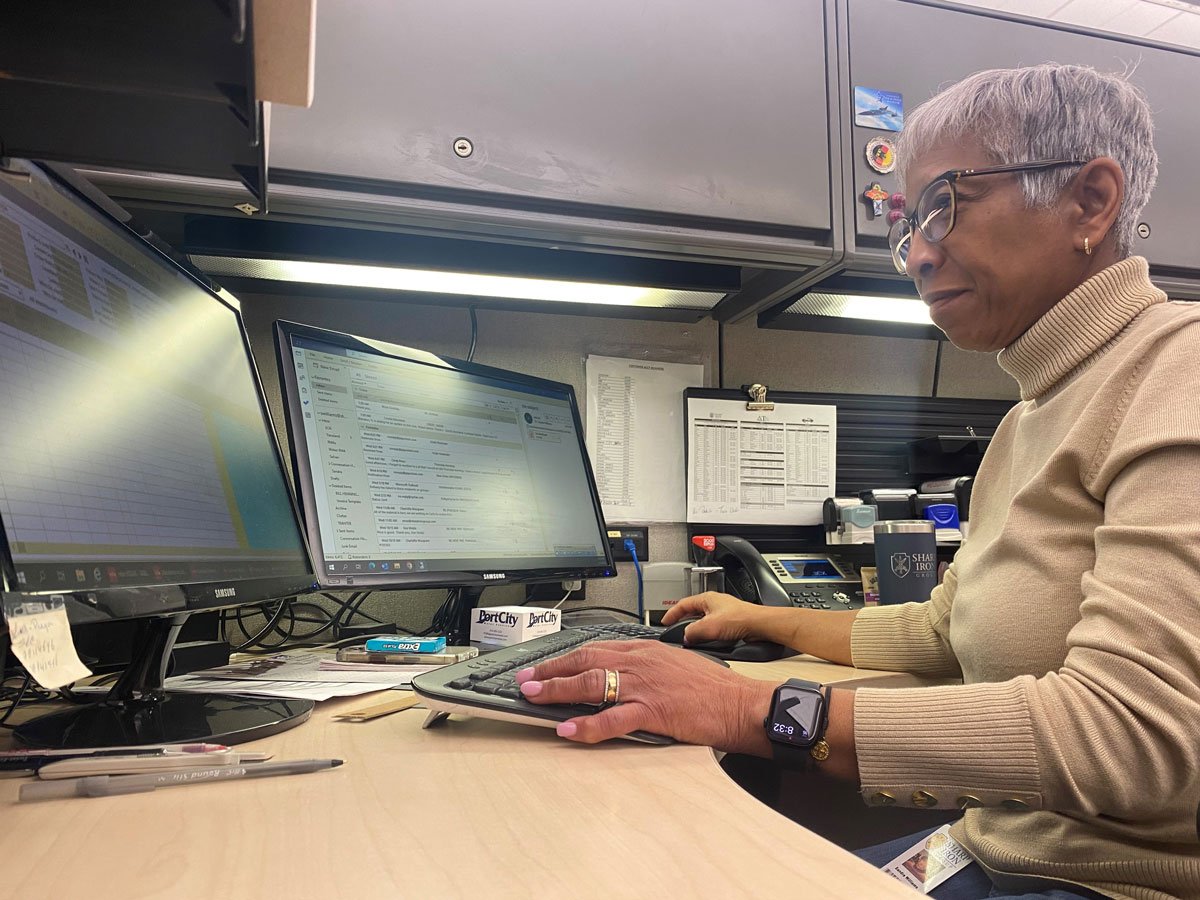

Sharp Iron Manufacturing

A Legacy of Success

-

Overview

Sharp Iron Manufacturing is an ISO-certified contract manufacturer, offering turnkey manufacturing solutions to our customers, enabling them to focus on their core business.

Sheet metal fabrication, precision machining, complex machined weldments, heavy fabrication projects, assembly and project management make up our core operational competencies.

-

Background

The company was formed in 2000 when James Frank, Managing Partner and CEO, acquired BW Fabricators, a company with a 40-year legacy of heavy fabrication, production welding, and field services in the water processing industry. Additional capabilities were added through the early years at the request of our customers. In 2004, a sheet metal and machining company was acquired and became Sharp Iron, specializing in precision sheet metal fabrication, precision machining, and light industrial assembly. In 2010, a low-voltage electrical controls operation, Armor Controls, was developed within Sharp Iron.

The four brands: BW Fabricators, BW Services, Sharp Iron, and Armor Controls, merged in 2011 under the umbrella of Sharp Iron Group. Michael Stanford joined the firm in 2014 as partner and President, bringing over 15 years of OEM aerospace manufacturing experience to the company. In 2015, we further refined our operational strategy by retiring the BW and Armor Controls brands, with all operations flying under the Sharp Iron flag.

In 2022, Sharp Iron Group launched Delta T Thermal Solutions. Delta T is the global producer of the PLATECOIL®, MAXCHANGER®, AND ECONOCOIL® heat transfer products. These products have an 80+ year legacy of proven success around the world and we are honored to carry on that legacy for decades to come. Learn more about this company at deltatthermal.com.

In 2024, we rebranded our manufacturing business in support of Sharp Iron Group’s strategy for growth, both organically and through acquisitions. The manufacturing business will become SHARP IRON MANUFACTURING, a wholly owned division of Sharp Iron Group. This will enable Sharp Iron to retain and build upon the name recognition and solid reputation that it has developed in the market for contract manufacturing while providing clarity and delineation for future growth opportunities.

SHARP IRON MANUFACTURING is the same company you’ve come to depend upon for high-quality manufacturing services for decades, and we look forward to serving you for decades to come!

-

Facilities

Sharp Iron Manufacturing operates two manufacturing plants in Wichita Falls, TX, totaling almost 200,000 square feet. The Hatton Road Plant specializes in sheet metal fabrication, precision machining, small weldments, and assembly. The Reilly Road Plant specializes in heavy fabrication projects, assembly, and painting. Our breadth of internal capability enables us to provide high-quality, cost-effective, delivery-focused solutions for our customers.

Sharp Iron Manufacturing operates under an ISO 9001 and AS9100 certified Quality Management System. We also maintain ASME pressure vessel certification (Section VIII, Div 1), on-site CWI (Certified Welding Inspector), on-site NACE II Inspector (coatings and surface finish) and several other customer-specific certifications. In addition, our Hatton Road Plant is ITAR registered and DD2345 certified. -

The Bedrock of Our Operation

The bedrock of our operation is found in Proverbs 27:17, “As iron sharpens iron, so one person sharpens another.”

We firmly believe that people and organizations thrive when they encourage and challenge one another as they strive toward continual improvement.

Our Mission

Our mission is to operate with an overall philosophy of INTEGRITY and LONG-TERM PERSPECTIVE.

To accomplish this, we must be HONEST in our communications, FAIR in our business practices and unwavering in our commitment to ETHICAL principles.

We will do this regardless of the cost, but expect that often the long-term benefits of integrity will help us thrive.

Our Quality Commitment

Sharp Iron Manufacturing is committed to meeting or exceeding our customer’s expectations.

We will commit the resources necessary to ensure compliance with requirements and to continuously improve our processes and services.

OUR OPERATIONAL TOUCHSTONES

Excellence = Quality always. Urgency = On-time, every time.

We are committed to these standards that, if achieved every time, will ensure that we exceed our customers’ expectations in the most efficient and profitable way possible.

These touchstones should be deeply embedded into the culture of our operations. Our customers should think of excellence and urgency when they think of Sharp Iron Manufacturing. If we cannot say with confidence that this is true, we still have work to do.

The 5 C's

We believe there are five key areas in which we must always concentrate to be successful – the 5 C’s.

CUSTOMERS – What needs are we meeting and for whom?

COWORKERS – Who is on our team? Who can help ? Who needs help?

COMMUNICATION – What, how and with whom do we need to share to accomplish the job?

CORE COMPETENCIES – What will people pay us for that we are both passionate about and great at doing?

COMPENSATION – Are we watching our pricing, costs and financial performance to ensure long-term growth and a quality workplace?